Blenders and Mixers in the Pharmaceutical Industry

Blenders and mixers are essential equipment used in the pharmaceutical industry for various purposes, including mixing, blending, homogenizing, and granulating of pharmaceutical powders, granules, and other solid materials. They play a critical role in achieving uniformity, consistency, and desired physical characteristics of pharmaceutical products.

Here are some common types of blenders and mixers used in the pharmaceutical industry:

-

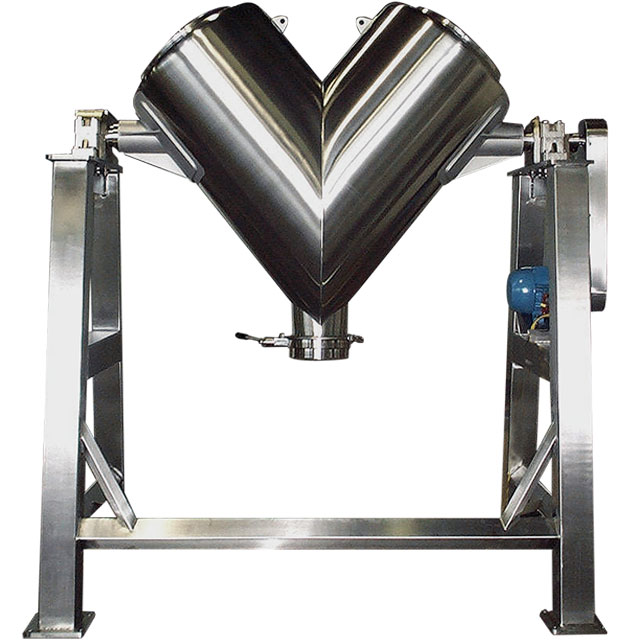

V-Blenders

V-blenders are commonly used for gentle blending of dry powders or granules. They have a V-shaped chamber with a central shaft that rotates, causing the materials to move in a tumbling motion. This type of blender is suitable for mixing ingredients with similar particle sizes and densities.

-

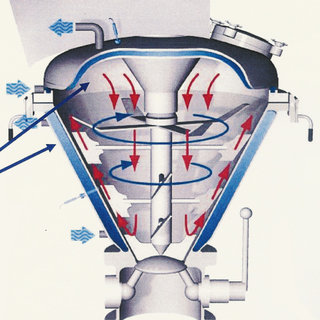

Double Cone Blenders

Double cone blenders consist of two conical-shaped chambers connected by a central shaft. The materials are loaded into one chamber, and as the blender rotates, the materials move back and forth between the two chambers, resulting in blending. Double cone blenders are versatile and can handle a wide range of batch sizes.

-

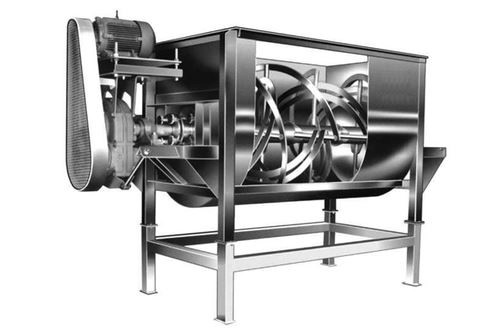

Ribbon Blenders

Ribbon blenders feature a horizontal trough with a central agitator consisting of inner and outer helical ribbons. The ribbons rotate in opposite directions, effectively mixing the materials. Ribbon blenders are commonly used for larger batch sizes and are suitable for both dry and wet blending applications.

-

Planetary Mixers

Planetary mixers utilize a rotating blade that moves around the mixing bowl while simultaneously rotating on its own axis. This dual motion ensures thorough mixing and blending of materials. Planetary mixers are versatile and can handle a wide range of viscosities, making them suitable for creams, ointments, and other semi-solid formulations.

-

High Shear Mixers

High shear mixers are used when intense mixing and dispersion are required. They consist of a rotor and a stator, creating a high-speed shearing action that breaks down particles and disperses them evenly throughout the mixture. High shear mixers are commonly used for emulsions, suspensions, and other formulations requiring fine particle size reduction.